How Long Does It Take to Build a Jeep Wrangler: Quick Guide

It typically takes about 24 hours of actual labor for a Jeep Wrangler to be built. The entire process from start to finish can span several days due to scheduling and logistics.

Aspiring Jeep Wrangler owners often wonder about the manufacturing timeline for their rugged vehicle of choice. These iconic off-road masters endure a meticulous build process that balances precision with efficiency. The assembly line at the dedicated Jeep production facility moves with clockwork regularity, ensuring each Wrangler meets the brand’s high standards.

A combination of advanced robotics and skilled human technicians come together, crafting everything from the robust frame to the signature interior features. This streamlined operation highlights Jeep’s commitment to quality and durability, promising adventurers a reliable partner for their off-road excursions. The specific build time for a Wrangler serves as a testament to the care and detail Jeep injects into every vehicle that rolls off the line.

Understanding The Process

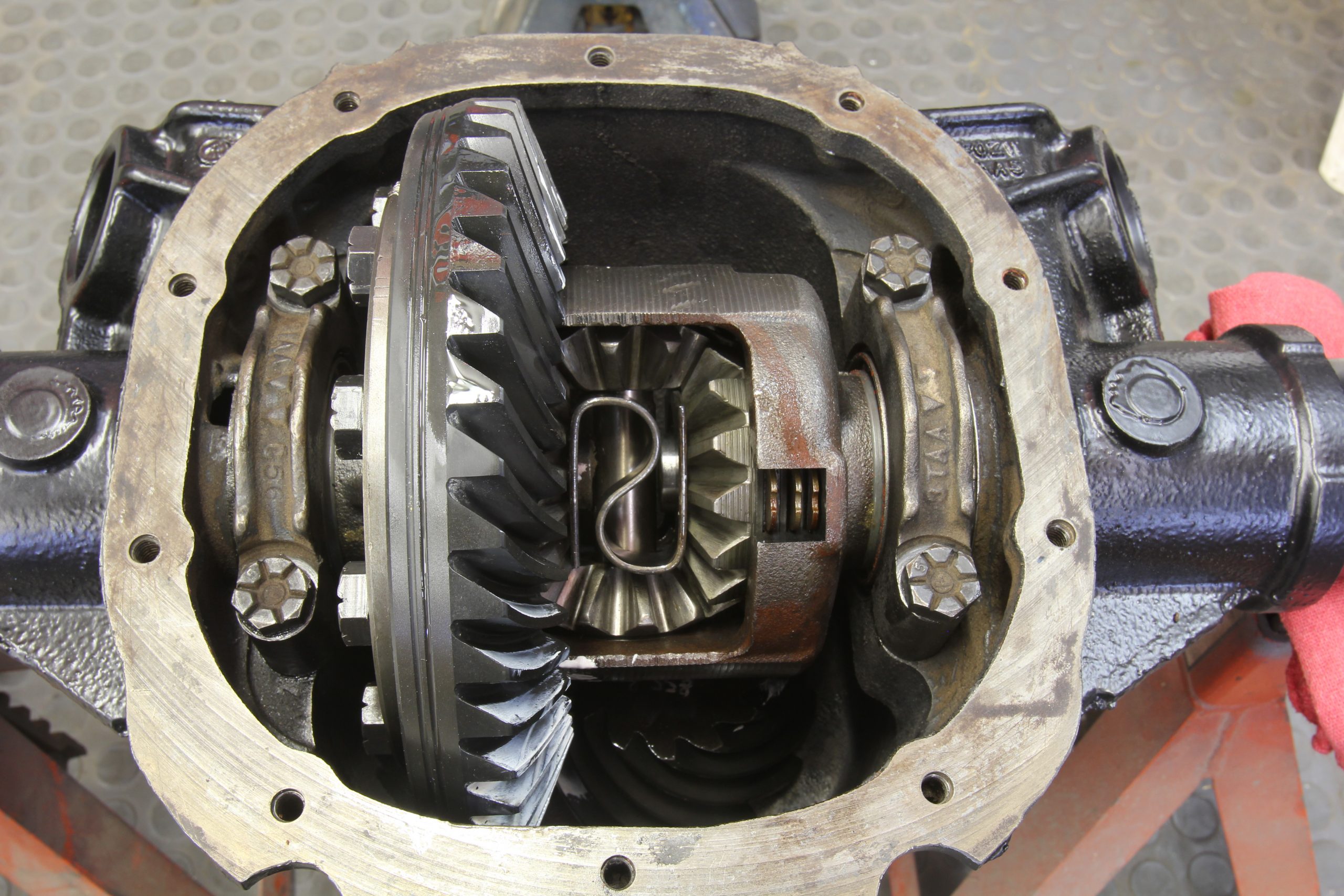

The time required to construct a Jeep Wrangler is influenced by various stages and factors. Generally, the assembly process involves chassis construction, powertrain installation, and body attachment, followed by painting and final inspection. Each stage meticulously combines precision robotics with skilled craftsmanship, ensuring every Jeep Wrangler meets high standards of quality and durability.

Key factors affecting build time include the current production load, availability of parts, and workforce efficiency. High demand or parts shortages can add time to the assembly process. There is also a distinction between personalization and standard models. Custom options such as unique colors, upgraded features, or additional modifications require extra time for integration and quality control checks, extending the overall build timeline compared to standard, off-the-line models.

| Stage | Description | Time Impact |

|---|---|---|

| Chassis Construction | Foundation build of the Jeep Wrangler | Depends on complexity |

| Powertrain Installation | Fitting of engine and drivetrain | Varies by powertrain options |

| Body Attachment | Joining the body to the chassis | Consistent across models |

| Painting | Application of color and protective coatings | Longer for custom hues |

| Final Inspection | Quality assurance checks | Additional time for personalized models |

Factors That Affect Build Time

The build time for a Jeep Wrangler can significantly vary based on several factors. The factory location and production capacity play a crucial role; a plant with high-volume output might expedite the assembly process, while factories in different regions could extend shipping times. Customizations and special requests also have a substantial impact on the timeline. Specific features or modifications requested by the buyer often necessitate additional time for intricacies in the manufacturing process.

Moreover, parts availability and supply chain issues can create unpredictable delays. A disruption in the steady flow of parts – such as those caused by global events or logistic challenges – may stall the production line, leading to longer wait times for the final assembly of the Jeep Wrangler. Each of these elements must be considered to understand the potential wait time from order to delivery.

Jeep Wrangler Build Timeline

The journey from ordering to production of a Jeep Wrangler is often steeped in anticipation. Typically, after placing an order, it might take anywhere from 6 to 8 weeks before the manufacturing process kicks off. This period can fluctuate based on demand and factory schedules.

Delving into the manufacturing and assembly line specifics, each Jeep Wrangler undergoes a structured build process. Precision robotics and skilled technicians work in harmony, ensuring that all components meet the strict quality standards set by Jeep. The time spent on the assembly line can vary, but the focus on quality never wavers.

Once the vehicle is assembled, it undergoes rigorous inspection to ensure every Wrangler adheres to Jeep’s high standards. The process of shipping and delivery follows the inspection, with new owners typically receiving their vehicles within 2 to 3 weeks after completion. This timeframe is subject to change based on logistical variables and geographic location.

Production Line Insights

The process of crafting a Jeep Wrangler is a blend of precision engineering and stringent quality checks. Typically, the assembly line of a Jeep Wrangler is a streamlined operation, designed to maximise both efficiency and product quality. Taking into account the various stages from the initial framework to the final product, the timeline for building a single vehicle can vary based on a number of factors.

Technological advancements have significantly reduced manual labor and improved the speed of production, ensuring that every vehicle meets exact manufacturer standards. Robots and automated systems work alongside human operators, contributing to the intricate process of assembling a Jeep Wrangler. Every vehicle that comes off the production line is subject to rigorous quality control procedures, ensuring that customers receive a product free of defects.

After the vehicle assembly is complete, the final touches are applied. These critical steps involve further inspections and any necessary adjustments to guarantee the Jeep Wrangler is ready for rugged use. This part of the process underscores the brand’s commitment to delivering a durable and reliable vehicle.

Reducing The Wait For Your Wrangler

Understanding the production timeline of a Jeep Wrangler is key for potential buyers. The process can vary, significantly impacted by factory demands and customization levels. Placing an order during low demand seasons, such as late fall or early winter, may lead to shorter wait times. Additionally, choosing a less popular color or trim might expedite the process as these variations often have quicker assembly lines.

To ensure a swift build and delivery, communication with the dealership is crucial. Establishing a clear line of dialogue can keep you informed about the Wrangler’s progress and potential delays. Selecting options that are readily available at the dealership may also reduce the overall timeframe. It’s essential for purchasers to have realistic expectations and patience during this period.

Credit: www.onallcylinders.com

Frequently Asked Questions Of How Long Does It Take To Build A Jeep Wrangler

What Is The Production Time For A Jeep Wrangler?

The production time for a Jeep Wrangler typically ranges from 8-10 weeks after placing an order.

Can I Track My Jeep Wrangler Build Progress?

Yes, with your order number, you can track your Jeep Wrangler’s build progress through the Jeep customer service or online tracking.

What Factors Affect Jeep Wrangler Build Time?

Jeep Wrangler build time can be affected by factory workload, customization options, parts availability, and overall demand.

Is Expedited Manufacturing Available For Jeep Wranglers?

Expedited manufacturing isn’t typically offered due to the complex assembly process and demand for Jeep Wranglers.

How Does Pre-ordering Impact Wrangler Build Time?

Pre-ordering can lead to earlier build start times but does not guarantee faster overall production time for your Jeep Wrangler.

Conclusion

Building your Jeep Wrangler is an adventure in itself, just as driving one. The timeline can vary, typically spanning six to twelve weeks. Remember, patience is key when creating a vehicle tailored to your adventurous spirit. Dream it, build it, and soon, you’ll be conquering the trails in your personalized Wrangler.