Expert Guide: Jeep 4.0 Flywheel Torque Specs Demystified

The Jeep 4.0 flywheel torque specs are 75 ft-lbs, according to the manufacturer’s specifications. The flywheel transfers the power generated by the engine to the transmission.

It is an essential component that needs to be installed correctly with the right torque specs to ensure smooth functioning and prevent any damage to the engine or transmission. In this article, we will cover the importance of flywheel torque specs, the tools required to torque the flywheel, and step-by-step instructions on properly torque the flywheel.

In this article, I will provide some tips Jeep 4.0 Flywheel Torque Specs. Whether you are a seasoned mechanic or a DIY enthusiast, this guide will provide all the information you need to complete the job.

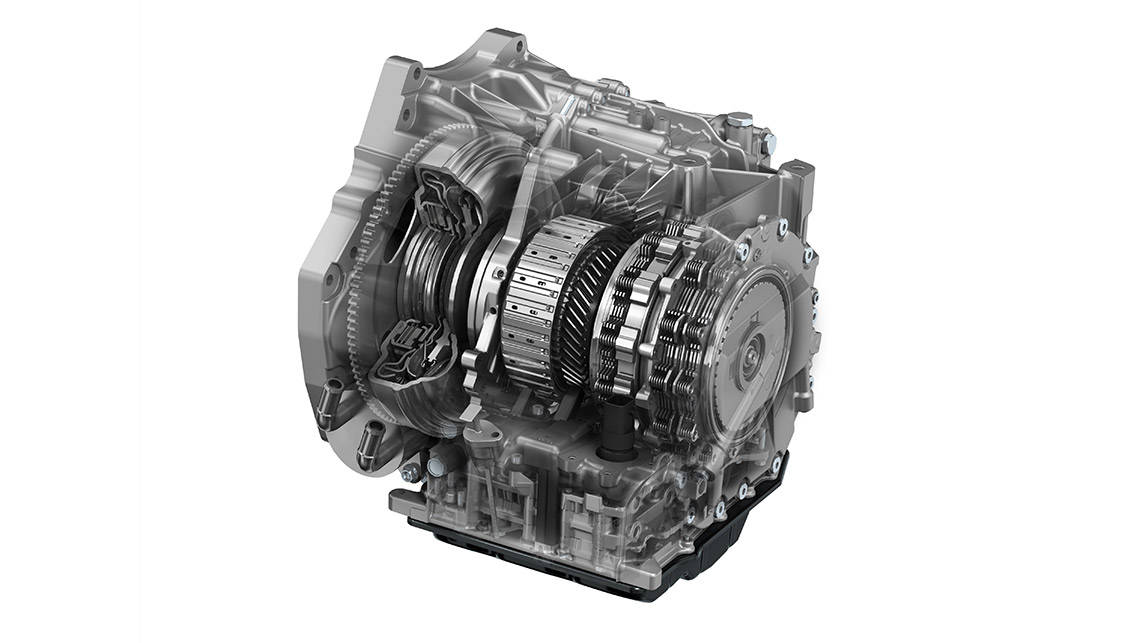

Credit: www.carsguide.com.au

Understanding The Basics Of Flywheel Torque Specs

Jeep 4.0 Flywheel Torque Specs

As an essential component of your jeep’s engine assembly, the flywheel serves as a crucial element that allows your vehicle to run. Understanding flywheel torque specs and their significance is critical for keeping your jeep running smoothly and avoiding potential mechanical issues that can result in costly repairs.

In this post, we will go over the basics of flywheel torque specs and everything you need to know about them.

What Are Flywheel Torque Specs?

Flywheel torque specs are the amount of force required to tighten the bolts that fasten the flywheel to the crankshaft. These specs are usually expressed in foot-pounds (lb-ft) or newton-meters (n-m) and are specific to your jeep make, model, and year.

It’s essential to adhere to the specified torque value to keep your engine running efficiently and prevent damage to the flywheel and the entire engine system.

Importance Of Flywheel Torque Specs

The proper tightening of the flywheel bolts is essential for the engine’s efficiency and durability. Here are the reasons why flywheel torque specs are essential:

- Prevents vibration: Tightening the flywheel bolts to the specified torque will ensure that the flywheel is secured to the crankshaft, preventing any vibration that can result in severe damage to the entire engine assembly.

- Uniform bolt tension: Correct torque specifications help achieve uniform bolt tension across all bolts, resulting in an even distribution of clamping force and minimizing the risk of bolts loosening over time.

- Prevents shearing of bolts: Over-tightened bolts are susceptible to shearing, which causes significant damage to the engine’s internal components. On the other hand, under-tightened bolts may lead to the flywheel’s loosening, causing the engine to stall.

Overview Of Related Terminologies

Knowing the tools that are required for tightening the flywheel bolts and their functions is crucial in understanding flywheel torque specs. Here’s a summary of some related terminologies:

- Torque wrench: This is a tool used to apply the specified amount of force or torque to the bolts to fasten the flywheel accurately. Torque wrenches prevent over-tightening or under-tightening, ensuring that the bolts are tightened to the correct specification.

- Impact wrench: An impact wrench is an alternative to using a torque wrench. They deliver a specific amount of torque and are generally used to remove bolts rather than fastening them. However, they can also be used to fasten bolts, albeit with the risk of over-tightening the bolts.

- Torque angle gauge: A torque angle gauge is used to measure the angle of rotation when tightening bolts rather than the amount of torque. This is necessary when flywheel torque specs determined by the angle the bolt is turned after applying the initial torque.

Understanding flywheel torque specs is vital in maintaining your Jeep’s engine. Adhering to the specified values using appropriate tools, such as torque wrenches, impact wrenches, or torque angle gauges, will ensure your engine runs smoothly and avoid expensive repairs.

Relevance Of Accurate Flywheel Torque Specs In Jeep 4.0 Engines

Jeep 4.0 Flywheel Torque Specs

The flywheel is an essential component in the Jeep 4. 0 engine, responsible for transmitting the power generated from the engine to the transmission. Therefore, accurate flywheel torque specs are crucial to the engine’s performance. In this blog post, we dive into the relevance of accurate flywheel torque specs in jeep 4.

0 engines, and the impact of inaccurate torque specs on their overall performance.

The Impact Of Inaccurate Torque Specs On Engine Performance

Inaccurate flywheel torque specs can impede the engine’s performance and lead to various malfunctions. Some of these malfunctions include:

- Excessive or insufficient input torque: This leads to a significant impact on the performance of flywheel, causing the engine to lose power and negatively impacts fuel efficiency.

- Clutch slippage and reduced clutch lifespan: If the torque specifications are loose, it results in clutch slippage and heat build-up, thereby reducing clutch lifespan and performance.

- Engine vibration: Incorrect torque specs cause the engine to vibrate, and can result in severe damage to engine components.

Common Symptoms Of Incorrect Torque Specifications

Inaccurate torque specifications can be identified through various symptoms, which include:

- Engine noise coming from the flywheel

- Difficulty in starting the engine

- Driveline vibrations at high speeds

- Clutch chatter and clutch slippage

- Transmission leakages

Overview Of The Flywheel Assembly Process In Jeep 4.0 Engines

A flywheel assembly is a robust and complex part of a Jeep 4. 0 engine, and it must be assembled correctly. The following is an overview of the flywheel assembly process for Jeep 4. 0 engines:

- The flywheel’s mounting surface must be cleaned to ensure even pressure distribution.

- The mounting bolts must be torqued to the required specifications, so you must use a torque wrench.

- The clutch assembly must be aligned correctly to the flywheel and torqued according to manufacturer specifications.

- Finally, the transmission must be installed, and all fasteners must be torqued appropriately using the manufacturer’s specifications.

Accurate flywheel torque specs play a vital role in the

Thus, it is critical to find the correct torque specifications to ensure the engine’s optimal performance.

Recommended Flywheel Torque Specs For Jeep 4.0 Engines

Jeep enthusiasts who are looking to torque their flywheel should note that the process is especially important for the 4. 0 engine model. Flywheel torque specs can vary depending on the engine model and flywheel material. In this blog post, we will explore the manufacturer-recommended torque specs for the jeep 4.

0 engine, torque specs for different engine models, and the impact of variations in torque specs for different flywheel materials.

Manufacturer-Recommended Torque Specs

To ensure that your flywheel is working effectively, following the manufacturer’s recommended torque specs is important. For the Jeep 4. 0 engine, the recommended flywheel torque specs are:

- 55 pounds-per-foot (lb-ft) for the oe cast iron flywheel.

- 75 lb-ft for aftermarket aluminum flywheels.

Torque Specs For Different Jeep 4.0 Engine Models

It is crucial to understand that torque specs can vary based on the 4. 0 engine model. Below are the flywheel torque specs for different jeep 4. 0 engine models:

- 55 lb-ft for 1994-1995 jeep wrangler yj and 1994-1995 jeep cherokee xj

- 75 lb-ft for 1996-2006 jeep wrangler tj and 1996-2001 jeep cherokee xj

- 80 lb-ft for 1999-2004 jeep grand cherokee wj

Different engine models have varying torque specifications and following them ensures that the flywheel is working at maximum effectiveness. Make sure to check the specific torque specs for your particular engine model before beginning any work.

Understanding The Variations In Torque Specs For Different Flywheel Materials

The type of flywheel material can influence torque specifications. For instance, aluminum flywheels are often used in high-performance vehicles because they are lighter than cast iron flywheels. However, the torque specs for aluminum flywheels are typically higher because they warp more easily than their cast iron counterparts.

As a result, following the manufacturer’s recommended torque specs for different materials is crucial in obtaining the maximum performance from your jeep 4. 0 engine.

By following the manufacturer’s recommended torque specs and understanding the variations for different engine models and flywheel materials, you can ensure that your jeep 4. 0 engine is performing at its best. If you’re unsure about the specifications for your jeep, it is always best to consult a mechanic or refer to vehicle manuals before performing any technical work.

How To Determine The Correct Flywheel Torque Specs For Your Jeep 4.0 Engine

Understanding The Torque Specifications In Your Jeep 4.0 Engine Manual

When it comes to maintaining your jeep 4. 0 engine, it’s essential to have an understanding of the appropriate torque specs for your flywheel. The flywheel plays a crucial role in transferring the power generated by the engine to the transmission.

The flywheel torque specs can be found in your jeep 4. 0 engine manual. Make sure that you use the appropriate specs for your engine, depending on the year and model.

Factors That May Affect The Correct Torque Specs

Several factors can affect the correct torque specs of your flywheel. These factors include the year and model of your jeep, the type of flywheel you have, and the bolts’ condition. Before you torque the flywheel, make sure to inspect the bolts carefully.

How To Use A Torque Wrench, Impact Wrench, Or Torque Angle Gauge To Achieve Accurate Torque Specifications

To achieve the correct flywheel torque specs, you can use three types of tools – torque wrench, impact wrench, or torque angle gauge. Here’s how to use them:

Torque Wrench

- Thread the bolts of the flywheel with a drop of thread locker to ensure they won’t back out

- Tighten the bolts with a torque wrench in a criss-cross pattern to prevent warping

- Make sure to torque in stages, starting at approximately 30 pounds. Increase the torque by increments every time, following the pattern.

Impact Wrench

- Note that using impact wrenches can result in applying too much torque

- It’s not suitable for old bolts that may snap due to excessive torque

- Make sure to check the torque with a torque wrench after using an impact wrench

Torque Angle Gauge

- Thread bolts with thread locker

- Tighten bolts in the correct sequence to the torque specification

- After achieving the torque spec reading, use the angle gauge to determine the correct degrees by tightening the bolts in a clockwise direction

By adhering carefully to these guidelines, you’ll be able to ensure that the torque specs of your jeep 4. 0 flywheel are accurate and reliable. Keeping an eye on these specifications is essential for maintaining the smooth operation of your jeep.

Frequently Asked Questions On Jeep 4.0 Flywheel Torque Specs

What Is The Jeep 4.0 Flywheel?

The jeep 4. 0 flywheel is part of the engine’s rotation system, connected to the crankshaft.

How Important Is The Flywheel Torque?

The flywheel torque is crucial to maintain stable engine operation and prevent damages to components.

What Are The Jeep 4.0 Flywheel Torque Specs?

The jeep 4. 0 flywheel torque specs are 75 lb-ft for the flywheel to crankshaft bolts.

What Tools Are Needed To Torque The Flywheel?

To torque the flywheel, you will need a torque wrench with a range of 50-150 lb-ft, an extension, and a socket.

How Often Should The Flywheel Bolts Be Re-Torqued?

The flywheel bolts should be re-torqued after 500 miles of usage and then checked regularly.

Conclusion

With the understanding that the torque specifications for the jeep 4. 0 flywheel can vary based on the year and model of the vehicle, it’s important to reference the correct chart before beginning any work. By utilizing the appropriate specifications and techniques, you can ensure that the flywheel is properly torqued to avoid any potential issues or damage down the road.

It’s also worth noting that a high-quality flywheel and clutch kit can make a significant difference in the performance of your jeep 4. 0, so it’s important to prioritize these components if you plan to drive your vehicle in challenging environments.

Ultimately, whether you’re performing diy repairs or turning to a professional mechanic, taking the time to research and apply the proper torque specs and techniques for your jeep 4. 0 flywheel is essential for maintaining optimal performance and safety.